Automated Flaggers Boost Safety on Paving Projects

Michelle Marsh, AWP Safety’s senior vice president of EHS, shares how automated flagger assistance devices, also known as AFADs, can support safe and efficient paving projects. Michelle’s article was also featured in AsphaltPro Magazine.

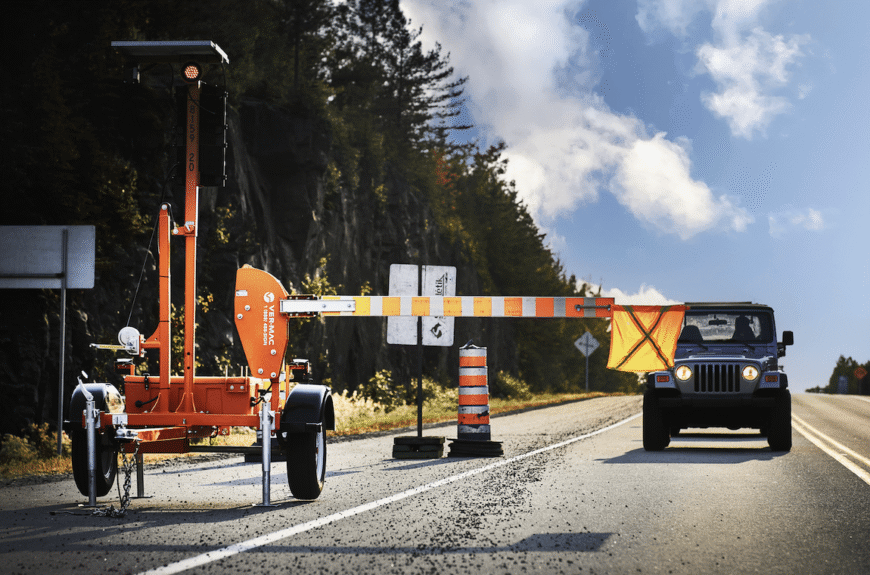

There’s a shift happening on the shoulders of our nation’s roads, and it’s not just new asphalt. It’s a change in how we manage traffic in active work zones. Imagine a sunbaked paving job and the familiar sight of a traffic flagger waving vehicles through the work zone. In the worker’s place is an automated flagger assistance device (AFAD).

AFADs are out there right now, helping paving crews stay safer, work faster, and face less risk from motorist inattention.

Flaggers are essential. They’re some of the most situationally aware, quick-thinking professionals on a job site. But they’re also highly vulnerable, often stationed just feet away from live traffic, exposed to speeding vehicles, distracted drivers and even incidents of motorist aggression.

We’ve all heard the stories, from workers being cursed out, to being clipped by mirrors, injured, or worse. In a work zone, even a split-second delay in reaction time can mean disaster. That’s why in some cases, removing flaggers from the danger zone altogether is the bold (and smart) move AFADs make possible.

About Automated Flaggers

These units are portable, remotely operated traffic control devices used in temporary, single-lane closures on two-lane roads. They typically feature red/amber signal lights or gate arms and are operated by a trained crew member from a safe location via remote control.

At AWP Safety, our AFADs are deployed with trained operators who stay in full visual contact with both ends of the closure zone—just like traditional flaggers—but with the added protection of being stationed well off the active roadway. They can respond instantly to changing conditions, communicate with the crew and activate emergency signals if a vehicle blows the stop, for instance.

The devices themselves are designed to be rugged, dependable and compliant with both the Federal Highway Administration’s Manual on Uniform Traffic Control Devices (MUTCD) and state-specific standards. And because they’re machines, they don’t get fatigued or distracted.

Breaking it down, AFADs are typically mounted on towable trailers and designed for temporary, single-lane closures, typical of what you’d find during shoulder work, rural resurfacing or bridge maintenance. The MUTCD approves two main types:

- Type 1: STOP/SLOW AFADs use a mechanical arm with a standard STOP/SLOW sign that rotates to display the correct message.

- Type 2: Red/Amber Lens AFADs operate more like a traditional traffic light, using red and amber signals with a gate arm to control flow.

At AWP Safety, we primarily deploy the Type 2 (signal head + gate arm) version for paving operations, being highly visible units that are compliant with both national and state department of transportation (DOT) standards.

Automated Flaggers In the FIeld

Here’s how AFADs are typically used in the field:

Setup: The AFAD unit is towed into position, stabilized on level ground and powered up. Most units operate off rechargeable battery packs, solar panels or portable generator support, depending on duration and conditions.

Wireless Connection: Each AFAD is operated via a remote-control console by a certified traffic technician located safely away from the traffic flow. This operator has full visibility of the lane closure area, often using spotters, mirrors or supplemental cameras when line-of-sight is compromised.

Communication Between Devices: For setups requiring two AFADs (one at each end of the single-lane closure), the units are digitally synced, meaning they communicate wirelessly to ensure both sides never show conflicting signals. When one end is set to STOP, the other cannot be switched to GO until clearance is confirmed.

Built-in Safety Locks: Most AFADs are designed with fail-safes. If the communication link drops, or if a system error is detected, the devices immediately default to STOP mode. And if a vehicle runs the gate, the operator can trigger a manual alert or engage emergency protocols.

Gate Arm: The presence of a physical gate arm adds a key psychological element: drivers are more likely to comply with a mechanical barrier than a human holding a paddle.

Mobility and Speed: The portability of AFADs means they can be deployed quickly (typically within 10–15 minutes) and moved as the work zone shifts throughout the day.

How You Can Benefit

At AWP Safety, we’ve taken it a step further by integrating our AFADs into broader Smart Work Zone packages. That includes sensor-based alerting, vehicle tracking and digital signage as part of a digital approach to elevating safety.

Not every job needs an AFAD unit. There’s still a place for traditional flaggers, especially in dynamic work zones that test even the most experienced protectors. But the moment the site allows for a machine to take the risk, why wouldn’t you use it?

The world is moving toward automation with a human touch. That’s what AFADs bring to paving: the reliability of tech, guided by experienced operators, with zero compromise on safety or compliance.

Learn more about AWP Safety AFAD’s, and request a free demo!